Asphalt milling, a crucial preparation for Albany construction projects, requires skilled contractors and right equipment. Choosing the appropriate machinery based on project size and asphalt type ensures efficient, sustainable removal. Safety training, gear, and protocols are vital to protect workers. Regular mill maintenance extends equipment life, enhances quality, and reduces costs, setting top contractors apart as reliable Albany asphalt milling solutions.

“Asphalt milling, a critical process for maintaining and upgrading roads in Albany, demands precision and expertise. This comprehensive guide equips local contractors with essential knowledge to excel in this specialized trade. We explore the fundamentals of asphalt milling, from selecting the right equipment to prioritizing safety measures. Moreover, we delve into maintenance practices that ensure longevity and superior results on your Albany contractual projects. Become an expert in asphalt milling today.”

- Understanding Asphalt Milling: Basics for Albany Contractors

- Choosing the Right Equipment: Key Considerations for Efficient Miling

- Safety First: Essential Practices for Safe Asphalt Miling Operations in Albany

- Optimal Mill Maintenance: Ensuring Longevity and Quality Results for Your Contractual Projects

Understanding Asphalt Milling: Basics for Albany Contractors

Asphalt milling is a critical process that involves removing the top layer of asphalt from roads, driveways, or parking lots to prepare the surface for repair, resurfacing, or complete replacement. For Albany contractors specializing in asphalt maintenance, understanding this technique is essential. It’s not just about tearing up pavement; it’s a precise method to create a clean slate for new asphalt applications.

This process is particularly crucial in urban areas like Albany where road conditions can vary greatly due to heavy traffic and weather fluctuations. A skilled asphalt milling contractor in Albany will know how to use specialized equipment, such as cold millers or wax machines, to strip away the asphalt while minimizing disruption to nearby properties. Moreover, they should be adept at managing the resulting milled material, often redirecting it for on-site recycling and repurposing as part of new paving mixtures, contributing to sustainable construction practices in residential driveway paving and sealing Albany projects and even asphalt overlay contractors for residential streets Albany.

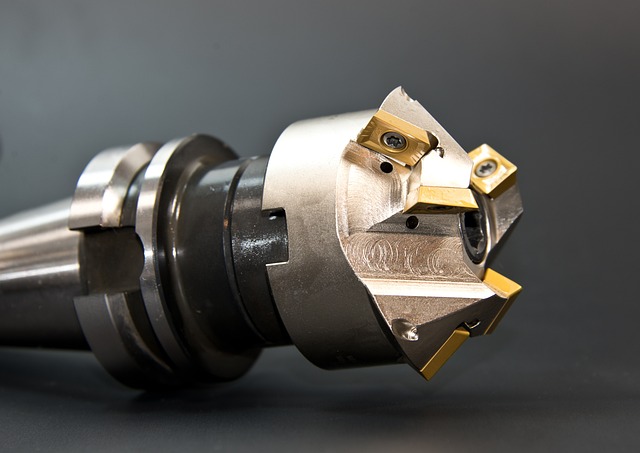

Choosing the Right Equipment: Key Considerations for Efficient Miling

When it comes to efficient asphalt milling, selecting the appropriate equipment is paramount. An asphalt milling contractor in Albany should consider several key factors to ensure optimal results. Firstly, the size and capacity of the milling machine should align with the project’s scope and scale. For residential streets, a smaller, maneuverable unit might be suitable, while larger projects may require more powerful machinery.

Additionally, the type of asphalt being milled is crucial. Different types of asphalt, such as hot mix asphalt (HMA) or cold mill cut, have varying properties that influence equipment selection. HMA Contracting Corp offers specialized services for both residential and commercial applications in Albany, NY, ensuring that their clients receive tailored solutions. Efficient milling also depends on effective removal of the milled material, so reliable removal services are essential. This includes considering the availability and capacity of trucks for disposal or recycling, contributing to a sustainable asphalt overlay process.

Safety First: Essential Practices for Safe Asphalt Miling Operations in Albany

When it comes to asphalt milling operations in Albany, safety should always be the top priority for any reputable contractor. Before beginning any project, ensuring your team is well-trained and equipped with personal protective equipment (PPE) is non-negotiable. This includes high-visibility vests, safety glasses, ear protection, and robust heavy-duty boots. Regular safety meetings and comprehensive training on operating heavy machinery safely are essential practices that every asphalt milling contractor in Albany should follow to prevent accidents and injuries.

Moreover, maintaining a clear line of communication is vital for creating a safe work environment. This involves establishing clear protocols for flagging down traffic, setting up efficient barrier systems, and ensuring consistent communication between the milling machine operator and ground crew. For commercial parking lot milling and patching or driveway resurfacing projects in Albany, adhering to these safety practices will not only protect your team but also contribute to a successful and seamless pavement restoration service, enhancing the overall quality of your work.

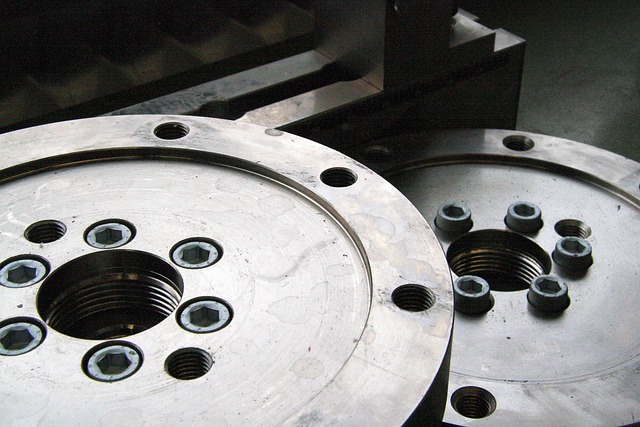

Optimal Mill Maintenance: Ensuring Longevity and Quality Results for Your Contractual Projects

Optimal mill maintenance is a cornerstone for any successful asphalt milling contractor in Albany. Regular upkeep ensures that your equipment operates at peak performance, delivering high-quality results on every project. This involves meticulous care and attention to detail, from routine inspections to prompt repairs and regular calibration of machinery. By adhering to these practices, you not only extend the lifespan of your tools but also maintain consistency in the final product—a smooth, even surface that meets industry standards.

For Albany-based parking lot overlay contractors, this translates into cost-effective solutions for clients. Well-maintained mills ensure efficient material removal and precise depth control, directly impacting the overall asphalt paving cost estimates. Moreover, blacktop installation and maintenance professionals in the region can leverage these advantages to offer competitive services, from quick repairs to complete resurfacing projects. This commitment to excellence is what sets top-tier contractors apart, ensuring customer satisfaction and long-lasting partnerships across various contractual projects.

For Albany’s aspiring or established asphalt milling contractors, mastering these essential practices can elevate your projects and solidify your reputation. By understanding the fundamentals, investing in suitable equipment, prioritizing safety, and implementing effective maintenance strategies, you’ll achieve superior results for every asphalt milling project. As you navigate the industry, remember that continuous learning and staying updated with best practices are key to standing out as a top-tier asphalt milling contractor in Albany.